Solving Social Issues Through Three Areas of Focus

Among the diseases where there are low levels of satisfaction, and from the perspective of seeking to improve social problems, our focus is on geriatric health, cancer supportive care, and women's health during different life stages. In the area related to the elderly, we focus on frailty, an aging condition estimated to rapidly increase in the aging society. Tsumura seeks to support all lives through Kampo medicine.

Kampo’s Quality Control Begins in the Field

Tsumura delivers Kampo formulations to patients in Japan through medical institutions after going through the process entirely controlled by Tsumura known as the Kampo value chain. It encompasses everything from the cultivation and the procurement of crude products that serve as the raw materials for Kampo to quality management, research, extracts manufacturing, distribution, and marketing. This integrated management is the source of providing a stable supply of high-quality Kampo products in Japan. In addition, the Kampo value chain has deep connections with nature which begin with the cultivation of crude products. By doing so, we seek to deliver the best Kampo to patients in Japan as efficiently and sustainably possible.

Manufacturing process of Kampo product

STEP 1

Cultivation and procurement

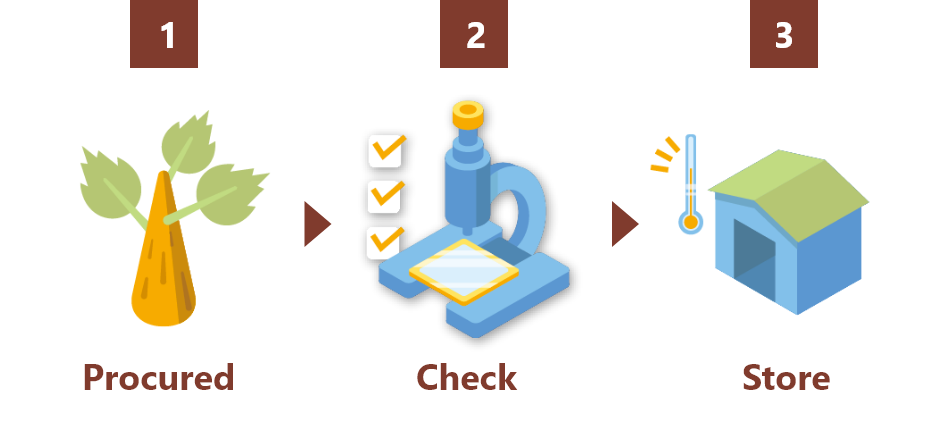

1

- Crude products (natural herbs) to be used as raw materials for Kampo preparations are cultivated and/or procured in China, Japan, Laos, and other countries.

2

- Crude products are analyzed to verify the amount of individual components as well as the presence of residual pesticides and microorganisms to ensure they comply with Japanese legal standards and our own in-house standards.

3

- Ingredients are stored in warehouses where temperature and humidity are strictly controlled.

STEP 2

Manufacturing

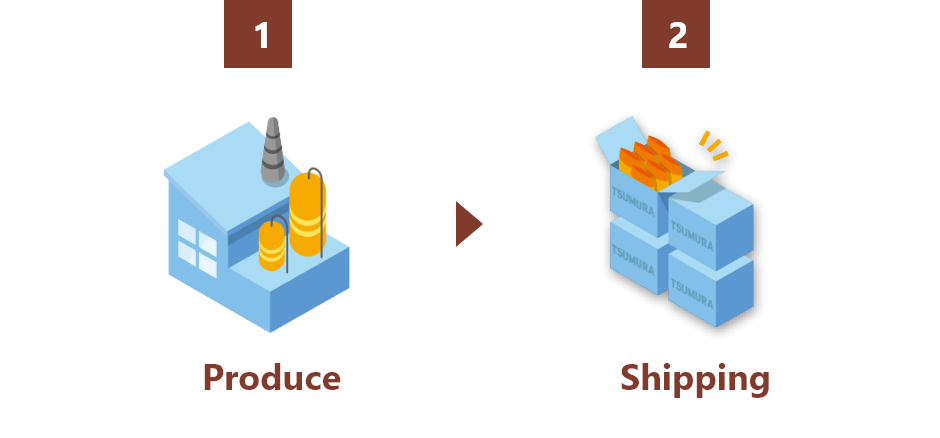

1

- Ingredients are crushed to extract a liquid essence using our own proprietary equipment based on traditional Kampo methods. After the liquid extract has been filtered, it is condensed at low temperature over a short period of time and dried instantly (to prevent the damaging effects of heat) to produce a powdered extract.

2

- The powdered extract is mixed with excipients (inactive ingredients) to form granules, which are then packaged, boxed, and shipped as finished products in Japan.

We aim to become a value-creating company that continues to grow with society, creating value for our community through the Kampo value chain, while meeting the United Nations Sustainable Development Goals (SDGs).